Press release -

Production start at Cermaq’s new closed containment system in Horsvågen

Cermaq aims to be leading in technology development that contributes to sustainable food production. This weekend, Cermaq transferred smolt into its new closed containment system in Horsvågen.

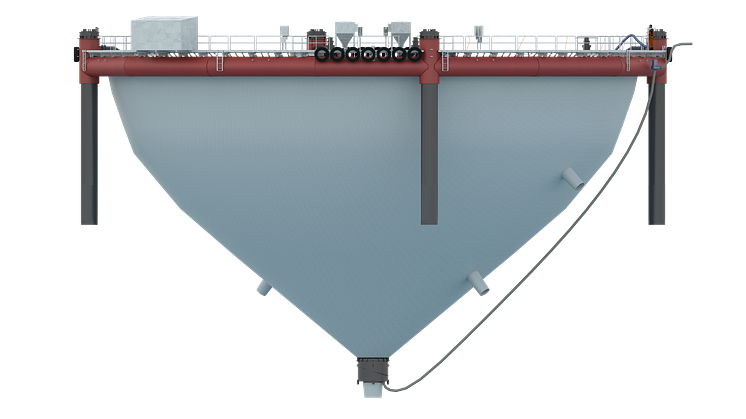

With this closed containment system Cermaq takes a first step towards developing closed farming technology. The closed containment system is built to provide maximum bio security and fish welfare. Water will be pumped into the pen from 13 meters depth, preventing sea lice from entering the pen. The tarp wall is made of strong and flexible composite, which minimizes escape risk. This is the world’s largest closed cage using flexible walls.

“We have been working on this project for a long time, and we are happy that we now are ready to put fish into the pen”, says Frode Holmvaag, Manager Seawater Nordland in Cermaq Norway. “This is new technology to us, and it will be very interesting to follow the growth and development of the fish in the new containment system”, says Holmvaag.

Cermaq focuses on innovations that improve sustainable farming on existing location in coastal areas. The new closed containment system, which has been constructed in partnership with Botngaard AS and Serge Ferrari, is certified for locations with a significant wave height of two meters, and can be used at most existing sea sites.

Botngaard has long experience with constructions for the aquaculture industry.

“The delivery and start up of the closed cage in Horsvågen mark a milestone for Botngaard and our development program for closed cages. We will now work together with Cermaq and our industry partners to further improve the technology and daily operations of the cage”, says Magnus Stendal, System Delivery Manager in Botngaard.

Serge Ferrari, world leader in innovative flexible materials, has developed the membrane wall that makes the containment system flexible and safe.

“After 6 years spent on R&D on various topics such as non-toxic formulation, as little elongation as possible and excellent lifetime, Serge Ferrari has come up with a new membrane dedicated to flexible closed cages: our Biobrane Aqua 2050. This highly secure fabric gives security against fish escape, more than ever”, says Gabriel Faysse, Market Manager Environment and Energy at Serge Ferrari.

Going forward, Cermaq will cooperate closely with groups of scientists to optimize the new closed containment system.

“There are still a lot of things we don’t know about closed containment systems. We see that closed containment systems in the ocean can play an important role in the aquaculture industry in the future, but it still requires further development”, says Harald Takle, R&D Manager Farming Technology in Cermaq Group. “This is why we have applied for development licenses with the FlexiFarm concept, which takes closed containment systems a giant step further as it will include cost-effective water treatment against infections and allow harvest size production in more exposed areas”, says Takle.

Facts about the closed containment system in Horsvågen:

- Production capacity: 400 tons biomass

- Circumference: 120 meters

- Volume: 10 400 m3

Contact: Frode Holmvaag, Manager Seawater Nordland. E-mail: frode.holmvaag@cermaq.com, tel.: +47 990 13 998.

Topics

Cermaq is one of the world's leading companies in farming of salmon and trout, with operations in Norway, Chile and Canada. Cermaq is a fully owned subsidiary of Mitsubishi Corporation with head office in Oslo, Norway.